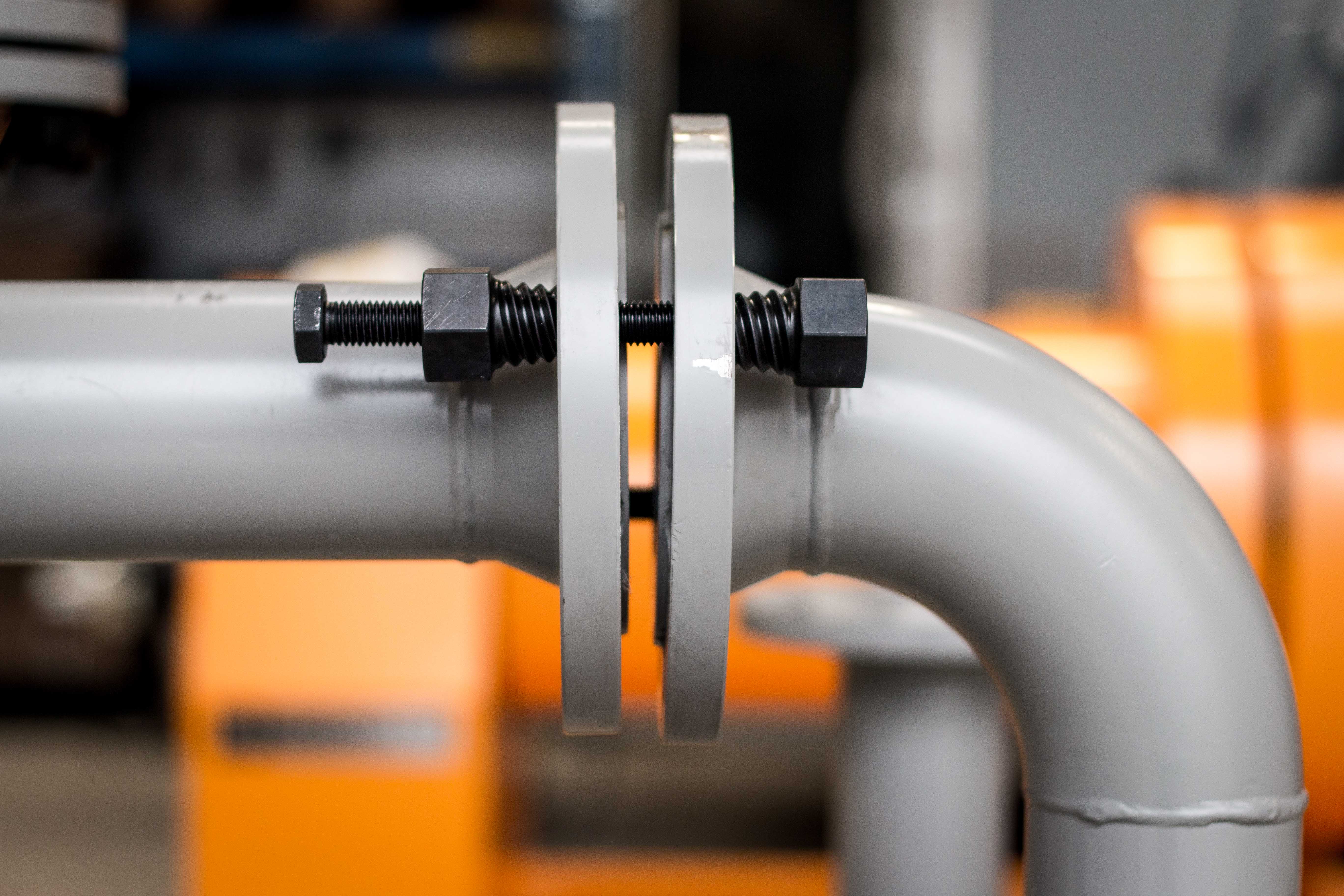

Festec Flange Spreader

Large gap or zero gap, the patented Festec® Flange Spreader spreads them all. It is easy to use, requires no large investments, is safe to handle and a extremely long lasting top-quality product.

In short, the Festec® Flange Spreader replaces conventional methods and is a must for mechanical plant maintenance technicians since 1985. Where other tools or methods might be too big, impractical or even cannot be used, the Festec® Flange Spreader always fits in bolted flange joints.

The Festec® Flange Spreader will fit in every toolbox due to its handy size and low weight. It is not much larger than a studbolt and requires mostly the same heavy duty spanner as used on the nuts of the studbolts in the flange joint to be separated.

The long press bolts of the Festec® Flange Spreader enables a wide opening of the flange connection and thus a thorough cleaning and inspection of the packing faces. Even flange joints without a gap can be spread safely. If used properly the Festec® Flange Spreader helps to avoid the risk of damaging the packing faces.

The Festec® Flange Spreader is used successfully by thousands of customers worldwide, such as refineries, (petro-)chemical and pharmaceutical industries, (nuclear) power-plants, paper– and steel-mills, food- and luxury industries, shipbuilding and offshore industry etc. as well as their contractors. It can be used to replace a gasket, orifice plate, ring joint or lens ring, fit a blind flange, clean or inspect packing faces, open joints on turbines, pumps, covers of heat exchangers, filters etc. The part with the press bolt can also be used for levelling heavy machinery.

The Festec® Flange Spreader can be used on flanges according ANSI, DIN, API and SP standards. For the right choice of size is referred to the selection table or the technical specification chart in the user manual or brochure.

Contact us nowFAQ

-

Where should the Festec® Flange Spreader be mounted?

The Festec® Flange Spreader can only be mounted in the bolt hole of the flange to be spreaded.

-

Why do you recommend to use 2 tools for spreading flanges?

When spreading a flange joint, it is recommended to use two tools set 180 degrees apart on the joint. When doing this you improve safety and have also more spreading force. You can also spread more evenly and this ensures that the flange gasket will not be damaged.

-

How to use the Festec® Flange Spreader?

Step 1: Remove 2 studbolts diagonally

Step 2: Insert the Flange Spreader and remove the rest of the studbolts

Step 3: Tighten the press bolt to achieve the required gap

-

On which flanges can the Festec® Flange Spreader be used?

The Festec® Flange Spreader can be used on flanges according ANSI, DIN, API and SP standards. The Festec® Flange Spreader should not be used on cast-iron flanges. For the right choice of size is referred to the selection table or the technical specification chart which you can find in the brochure and user manual.

-

What is the spreading capacity of the Festec® Flange Spreader?

If mounted and tightened properly, a safe spreading capacity up to 10 tonnes can be achieved (this is depending on which type of Festec® Flange Spreader is used).

-

What is the warranty of the Festec® Flange Spreader?

As the Festec® Flange Spreader is a extremely long lasting top-quality product, the tools have a lifetime warranty when using it according to the user manual.

About FESTECTOOLS

FestecTools are high quality specialty products which are suited for multiple industries. The product program contains a diversity of flange tools and safety shields for flanges and valves which are sold all around the world since the company founding in 1985.

Contact us now for more information

Festec Trade B.V.

Ecustraat 55

4879 NP Etten-Leur

The Netherlands

E: info@festec.nl

T: +31 (0)76 3030500

CoC: 24156127

VAT nr.: NL806819212B01